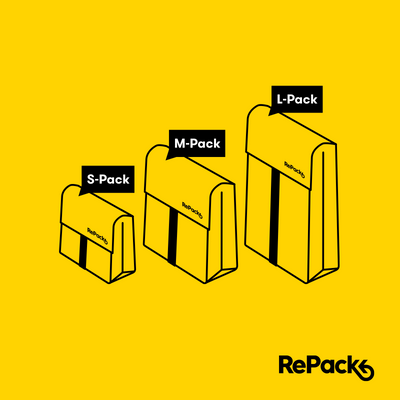

RePack Bags

Yet while RePack bags are made of 100% recycled polypropylene plastic made from PET bottles – that is not their only eco-friendly aspect. Once a RePack bag has been used for a delivery it can be reused for a minimum of 20 cycles - and often far more than that – until they are worn out, saving at least 20 single-use packages from landfill, incineration or polluting the land or ocean. Folding to the size of a letter, they are then returned to be upcycled, reducing CO2 emissions created by traditional single use throwaway packaging by 37 grams per individual shipment, which all adds up quickly. But that is not all.

RePack uses no water to clean returned bags, and every returned RePack reduces solid waste and removes the need to manufacture a new single-use plastic bag or a cardboard box.

This further reduces CO2 emissions by between 100 to 300 grams for a cardboard box, and a plastic bag by between 200 to 500 grams. RePack is also supported by a reward system that supports voucher use, charity donations and loyalty programs.

To read more about RePack click here

PolyBags

Afterglow’s garment poly bags are produced using 100% recycled low density Polyethylene (LDPE) sourced in-house by our supplier. Each bag has a zip-lock, so it can be reused repeatedly and is fully biodegradable and compostable, even if it ends up in a normal landfill.

Our supplier makes its plastic by recycling LDPE plastic materials, including plastic bottles and fishing nets that are worn out, abandoned or collected directly from the oceans, minimising the hazard of ghost nets, and reducing their adverse effect on the marine environment.

An organic additive is introduced during the bag manufacturing process, which accelerates the biodegradation of treated plastics in anaerobic landfills. The result is that these microbes excrete exactly the same waste as organic matter and will naturally decompose within a few years. This can also be captured to produce clean energy – but won’t affect its recycling capabilities.

Afterglow's poly bags are also Intertek Green Leaf Certified. Intertek's Green Leaf Mark is a consumer product and systems process that independently verifies a company’s environmental claims. Also exceeding other international sustainability standards, such as REACH and Oeko-Tex, our supplier's goal is to produce products that are made with materials that are both sourced from nature and can be returned safely back to the environment.

Packaging Boxes

The greenest packaging of its kind on the market, Afterglow’s packaging boxes, for our smaller orders under a certain weight, are manufactured by an ISO 14001 certified company who specialise in sustainably sourced, plastic free and biodegradable products.

All of Afterglow’s packaging boxes are made from 100% recycled and fully biodegradable paperboard that is certified by the Forest Stewardship Council, a global forest certification focused on responsible Forest Management and Chain of Custody.

All of the boxes are printed with eco-friendly vegetable and water based inks. Our supplier is the only packaging supplier to ensure ensure that every single box they make is guaranteed to be environmentally green.

Packing Tape

All Afterglow deliveries are packaged using eco-friendly packaging tape made by Tesa, one of the world’s leading manufacturers of technical adhesive tapes and self-adhesive system solutions.

Our polypropylene plastic film packaging tape is made from 100% recycled materials and is free from PVC and solvents, with a core made from 100% recycled cardboard - Read more

Our alternative packaging tape is made with 60% bio materials, and features a strong backing made from unbleached paper, and a core made from 100% recycled cardboard - Read More

A supporter of the UN Global Compact, the world’s largest corporate sustainability initiative, our packaging tape supplier is committed to producing sustainable products sourced from natural materials – as well as to eliminate, or considerably reduce, the use of solvents in their production processes.